Quick Guide to Vermeer Trommel Screens

September 22, 2022

Tackle your industrial screening production needs

Are you handling waste and recycling management in your business? A trommel screen can help you efficiently separate materials to optimize your worksite operations. Westerra Equipment is a proud dealer of industry-leading Vermeer equipment. With decades worth of expertise in specialized tree care and recycling equipment, when you buy Vermeer, you get powerful and innovative performance.

Not sure if a trommel screen is right for you? We put together a quick guide to walk you through the key considerations.

What is a trommel screen?

A trommel screen is a specialized piece of equipment used to separate different material grades. Aggregates are fed into a rotating drum that allows fine material to fall through while holding larger material.

Vermeer makes several models to cater to your unique business needs.

| TR5300 | TR521 | TR626 | |

|---|---|---|---|

| Gross Horsepower | 74 hp (55 kW) @ 2600 rpm and 181 ft-lb (245.4 Nm) of torque @ 1600 rpm | 120 hp | 134 hp (93.2 kW) @ 2400 rpm, 398 ft-lb (531.6 Nm) of torque @ 1600 rpm |

| Drum Diameter | 5 ft (1.5 m) | 5 ft (1.5 m) | 6 ft (1.8 m) |

| Transport Length | 39 ft (11.9 m) | 46.5 ft (14.2 m) | 54.5 ft (16.6 m) |

| Capacity | 100 cu yd (76.5 m3) per hr with .5" (12.7 mm) screens installed and material with moisture less than 40% | Approximately 150 cu yd (114.7 m³) per hr with .5" (1.3 cm) screens installed and material with moisture less than 40% | Approximately 200 cu yd (152.9 cu m) per hour with .5" (1.3 cm) screens installed and material with moisture less than 40% |

| Hopper Capacity | 5.5 cu yd (4.2 cu m) | 5 cu yd (3.8 cu m) | 6 cu yd (4.6 cu m) |

Horsepower: 74.0 hp

Hopper Capacity: 6.0 cu yd

Horsepower: 125.0 hp

Hopper Capacity: 6.0 cu yd

Get a closer look

What industry is the trommel screen best for?

Trommel screens are commonly used by compost operations, mulch manufactures, nursery and landscape operations, municipalities, and excavation and construction companies.

Need a trommel screen for a one time project? Rent one with Westerra Equipment today.

What size trommel screen should I get?

Factors to consider when choosing the right trommel screen include the desired production rates, machine design, and screen and drum customizations. Speak to our team to be matched with the best machine for our business needs.

What makes Vermeer trommel screens different?

Quick loading

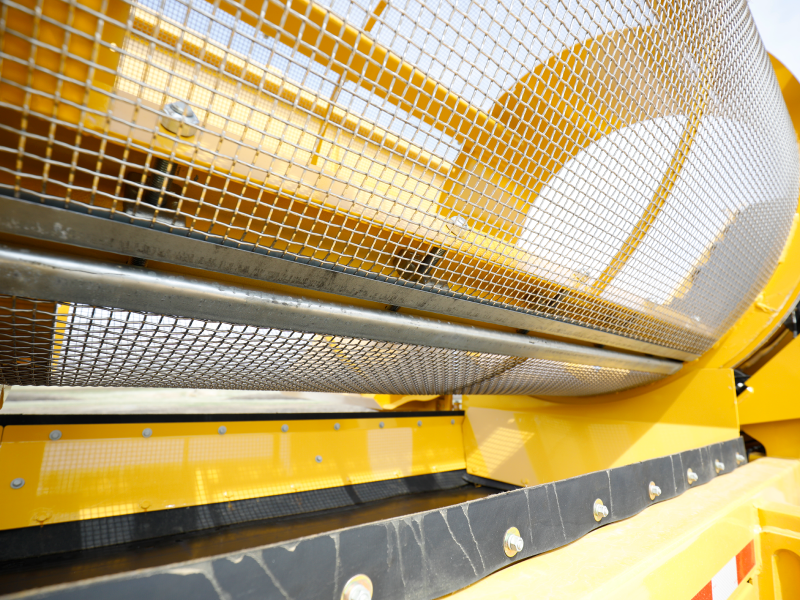

Ditch the loading ramp. Vermeer trommel screens are designed with large feed hoppers sitting low to the ground for quick and easy loading. A common configuration is the optional grizzly screen attachment mounted over the hopper. This keeps large material out, thus minimizing risk of damage to screens and creating consistent overs material.

Towable configuration

Available in the towable configuration, Vermeer trommel screens are easily transported around your jobsite. Position the finished product where you need it and load materials directly into a truck or stockpile with a radial stacking conveyor.

Ease of access

A large engine platform gives operators easy access for service and maintenance. While the reversible drum and feed conveyor help to minimize risk of jams, removable dual side panels expose the full length of the drum making it easy for maintenance and removal from ground level.

Tension screen design

Vermeer uses a unique tension screen design which increases open screen area for optimized production. Operators can quickly adjust the screen opening size, wire gauge, and type of wire to get the desired end-product size. This is done via five large bolts adjusted by the tensioning hooks – a much more efficient method than traditional bolt on screens.

Enhanced operator controls

Engineered with two discharge conveyors, operators can control the angle of these belts easily. The control station and displays are easily accessible to view machine data during operations. And with the optional radio remote control, operators can monitor and adjust the machine all while in the cab of their loader.

Vermeer also offers a variety of drums that can be changed based on application and end-product needs. Speak to a Vermeer specialist to learn more about these options.

Are there electric options?

Vermeer has expanded their recycling equipment range to include electric powered alternatives. The TR5300EM and TR626EM Electric Trommel Screens provide operators with zero exhaust emissions, reduced jobsite noise, and less machine maintenance on top of all the same accessibility and design benefits as their diesel counterparts. Both models include an industrial duty, fully enclosed and fan cooled Siemens electric motor.

| TR5300EM | TR626EM | |

|---|---|---|

| Engine | 60 hp (44.7 kW) Siemens motor | 150-hp (112-kW) Siemens motor |

| Drum Diameter | 5 ft (1.5 m) | 6 ft (1.8 m) |

| Transport Length | 39 ft (11.9 m) | 54.5 ft (16.6 m) |

| Capacity | 100 cu yd (76.5 m3) per hr with 0.5-in (12.7-mm) screens installed and material with moisture less than 40% | Approximately 200 cu yd (152.9 cu m) per hour with 0.5 in (1.3 cm) screens installed and material with moisture less than 40% |

| Hopper Capacity | 5.5 cu yd (4.2 cu m) | 6 cu yd (4.6 cu m) |

Horsepower: 60.0 hp

Hopper Capacity: 1.5 cu yd

Horsepower: 150.0 hp

Hopper Capacity: 1.6 cu yd

Stay green on the job and choose electric machinery for your recycling tasks. Improve operator work conditions with zero emissions and reduced noise disturbance. Also help you bottom line with less maintenance costs without forgoing performance designs.